Prestressed Power Spring PPS-001

Materials:Including SUS301 and precision steel strips, with customization available to suit your application.

Thickness : 0.04 - 1.0mm

Width : 2.5 - 90mm

Features:Pre-wound with internal pre-stress, delivering stable and high torque with quick response. Offers long service life, high reliability, easy assembly, and user-friendly operation.

Applications:Used in devices that require a higher number of spring turns to operate, such as fall arresters, air (or water) hose retractors, and automotive seat belts.

- Material : Type 301 stainless steel is typically used for most applications. High-carbon steel and other materials may be required.

- A wide variety of materials are available for use depending on your application.

- Thickness : 0.04 - 1.0mm

- Width : 2.5 - 90mm

Introduction

[Prestressed Power Spring] / [Customized Prestressed Power Spring]Prestressed Power springs are made of rectangular section material, are wound flat, and have either special retaining holes or bends on both ends. As the length-to-thickness ratio (L/t) increases, the spiral space between coils increases rapidly. To reduce the space required and maintain a reasonable amount of deflection (turns), prestressed power springs are retained in some type of housing or case in application.

Feature of Spring

[Prestressed Power Spring]

.jpg)

1. Material

2. T=Material thickness

3. W=Width

4. Da=Shaft diameter

5. Di=Inside diameter of holder

(Outside diameter of spring)

Application

[Prestressed Power Spring]

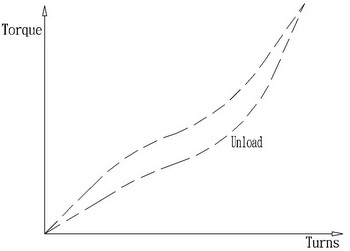

However, prestressed powers can store 25%~55% greater energy than power springs. It also has higher turns than power spring when their sizes are the same.

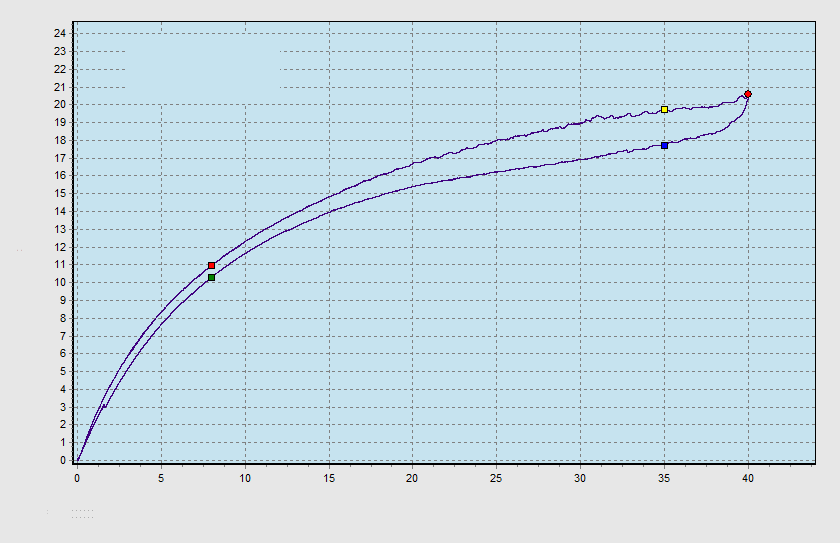

Power Diagram

[Prestressed Power Spring]

Torque Graph

● 20.572001 kg-cm Maximum Torque

Data Point 01 = 10.966kg-cm (coil 8)

Data Point 02 = 19.741kg-cm(coil 35)

Data Point 03 = 17.728kg-cm(coil 35)

Data Point 04 = 10.301kg-cm (coil 8)

K (Slope) Value = 0.3250 kg-cm/rev

kg-cm

KP25-000152